Table of Contents

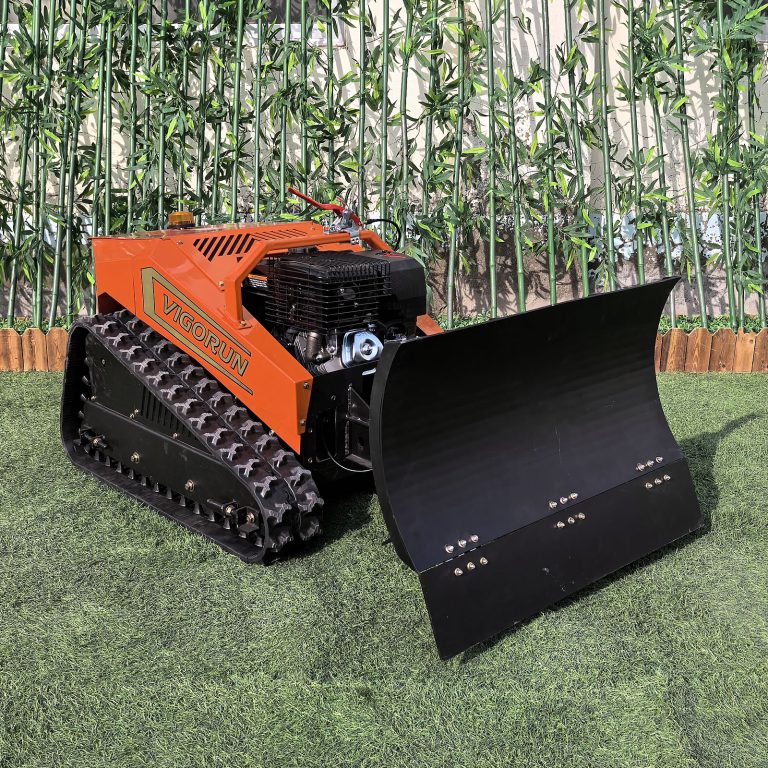

Features of the 2 Cylinder 4 Stroke Gasoline Engine Electric Motor Driven Compact Remote-Driven Angle Snow Plow

The 2 cylinder 4 stroke gasoline engine electric motor driven compact remote-driven angle snow plow is powered by a robust V-type twin-cylinder gasoline engine. This specific model, featuring the Loncin brand LC2V80FD engine, operates at a rated power of 18 kW at 3600 rpm. With a displacement of 764cc, it ensures strong performance and reliability, making it an ideal choice for tackling heavy snow removal tasks.

The 2 cylinder 4 stroke gasoline engine electric motor driven compact remote-driven angle snow plow is powered by a robust V-type twin-cylinder gasoline engine. This specific model, featuring the Loncin brand LC2V80FD engine, operates at a rated power of 18 kW at 3600 rpm. With a displacement of 764cc, it ensures strong performance and reliability, making it an ideal choice for tackling heavy snow removal tasks.

Equipped with a sophisticated clutch system, this engine engages only when it reaches a predetermined rotation speed, enhancing operational efficiency. This feature allows for smooth transitions and effective power management, which is essential when navigating challenging terrains during snow removal operations.

In addition to its powerful gasoline engine, the snow plow incorporates advanced features such as two 48V 1500W servo motors. This configuration not only provides substantial power for climbing but also enhances overall performance. The built-in self-locking function of the machine ensures that it remains stationary unless both power is on and throttle is applied. This safety mechanism significantly reduces the risk of unintended sliding, making it safer to operate in slippery conditions.

Equipped with a sophisticated clutch system, this engine engages only when it reaches a predetermined rotation speed, enhancing operational efficiency. This feature allows for smooth transitions and effective power management, which is essential when navigating challenging terrains during snow removal operations.

In addition to its powerful gasoline engine, the snow plow incorporates advanced features such as two 48V 1500W servo motors. This configuration not only provides substantial power for climbing but also enhances overall performance. The built-in self-locking function of the machine ensures that it remains stationary unless both power is on and throttle is applied. This safety mechanism significantly reduces the risk of unintended sliding, making it safer to operate in slippery conditions.

Operational Advantages and Versatility

The 2 cylinder 4 stroke gasoline engine electric motor driven compact remote-driven angle snow plow boasts a high reduction ratio worm gear reducer. This design amplifies the already impressive torque from the servo motors, providing exceptional output torque for climbing resistance. Additionally, even in a power-off state, the friction between the worm and gear ensures mechanical self-locking, preventing any downhill sliding during power loss. Equipped with an intelligent servo controller, this snow plow precisely regulates motor speed while synchronizing the left and right tracks. This capability allows the machine to maintain a straight line without needing constant remote adjustments, reducing operator workload. Consequently, this feature also minimizes risks associated with overcorrection, especially on steep slopes.

Equipped with an intelligent servo controller, this snow plow precisely regulates motor speed while synchronizing the left and right tracks. This capability allows the machine to maintain a straight line without needing constant remote adjustments, reducing operator workload. Consequently, this feature also minimizes risks associated with overcorrection, especially on steep slopes.