Table of Contents

Features of the Agriculture Gasoline Powered Cutting Width 1000mm Tracked Remotely Controlled Slasher Mower

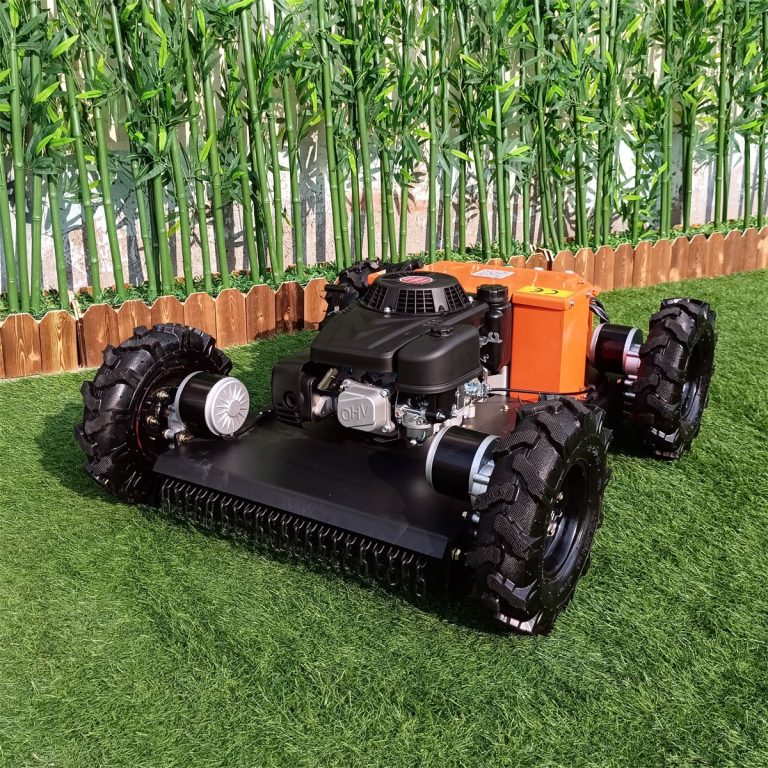

The agriculture gasoline powered cutting width 1000mm tracked remotely controlled slasher mower is engineered to deliver exceptional performance in various agricultural tasks. It is equipped with a robust V-type twin-cylinder gasoline engine, specifically the Loncin brand model LC2V80FD, which provides a rated power of 18 kW at 3600 rpm. This powerful 764cc engine ensures strong performance, making it ideal for heavy-duty applications.

The design of the engine includes a clutch that engages only at predetermined rotation speeds. This feature enhances the efficiency of the mower by ensuring optimal power delivery when needed while preserving fuel consumption during idle periods. The combination of power and precision makes this machine an invaluable tool for farmers and land managers.

In addition to its powerful engine, the agriculture gasoline powered cutting width 1000mm tracked remotely controlled slasher mower incorporates advanced safety features. The built-in self-locking function allows the machine to remain stationary without throttle input, effectively preventing unintended movement. This innovation significantly enhances operational safety, especially on uneven terrain.

The agriculture gasoline powered cutting width 1000mm tracked remotely controlled slasher mower is engineered to deliver exceptional performance in various agricultural tasks. It is equipped with a robust V-type twin-cylinder gasoline engine, specifically the Loncin brand model LC2V80FD, which provides a rated power of 18 kW at 3600 rpm. This powerful 764cc engine ensures strong performance, making it ideal for heavy-duty applications.

The design of the engine includes a clutch that engages only at predetermined rotation speeds. This feature enhances the efficiency of the mower by ensuring optimal power delivery when needed while preserving fuel consumption during idle periods. The combination of power and precision makes this machine an invaluable tool for farmers and land managers.

In addition to its powerful engine, the agriculture gasoline powered cutting width 1000mm tracked remotely controlled slasher mower incorporates advanced safety features. The built-in self-locking function allows the machine to remain stationary without throttle input, effectively preventing unintended movement. This innovation significantly enhances operational safety, especially on uneven terrain.

Versatility and Efficiency

One of the standout features of the agriculture gasoline powered cutting width 1000mm tracked remotely controlled slasher mower is its versatility. It can accommodate various front attachments, including a 1000mm-wide flail mower, hammer flail, forest mulcher, angle snow plow, and snow brush. This adaptability makes it suitable for a range of tasks such as heavy-duty grass cutting, shrub and bush clearing, vegetation management, and snow removal.

The machine utilizes two powerful 48V 1500W servo motors that provide impressive climbing capability. The intelligent servo controller precisely regulates motor speed, allowing the mower to traverse steep slopes without constant remote adjustments. This ensures that operators can focus on their tasks without the burden of over-correcting, enhancing both productivity and safety.

One of the standout features of the agriculture gasoline powered cutting width 1000mm tracked remotely controlled slasher mower is its versatility. It can accommodate various front attachments, including a 1000mm-wide flail mower, hammer flail, forest mulcher, angle snow plow, and snow brush. This adaptability makes it suitable for a range of tasks such as heavy-duty grass cutting, shrub and bush clearing, vegetation management, and snow removal.

The machine utilizes two powerful 48V 1500W servo motors that provide impressive climbing capability. The intelligent servo controller precisely regulates motor speed, allowing the mower to traverse steep slopes without constant remote adjustments. This ensures that operators can focus on their tasks without the burden of over-correcting, enhancing both productivity and safety.